OEM/ODM Manufacturer Cerium Oxide Polishing Powder - FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools – SinoDiam

OEM/ODM Manufacturer Cerium Oxide Polishing Powder - FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools – SinoDiam Detail:

FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCC58

|

Main Element | Fe, Co, Cu |

| Theoretical Density | 8.58g/cm³ | |

| Sintering Temperature | 850℃ | |

| Bending Strength | 1400Mpa | |

| Hardness | 98-102HRB |

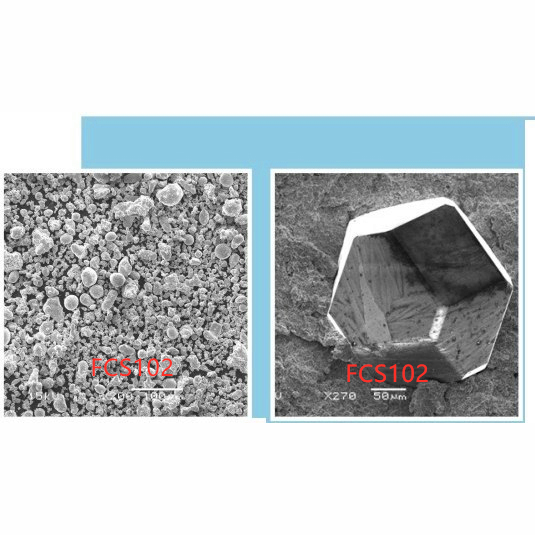

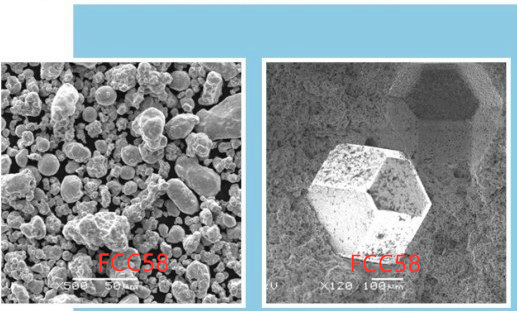

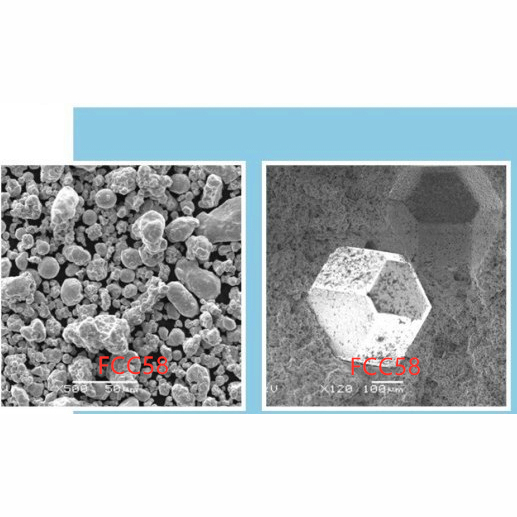

3. FCC58 Pre-alloyed Powder Character

- The powder has good wetting ability to the diamond and great mechanical granulating to other metal powders, the bond has a high toughness, strong impact resistance.

- Can be used on high quality diamond tools produciton, such as the diamond wire, diamond core bits, high quality granite saw blade, ceramic cutting blade

4. Usage Instruction for High Quality Ceramic Cutting Blade

- Metal Powder

- 30-50% FCC58

- + 3-8% Ni

- +25-35% Cu

- + 5-8% Sn

- + Fe for the balance

B. Diamond

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Diamond Concentration @ 9-12%

C. Sintering Temperature 840-860℃

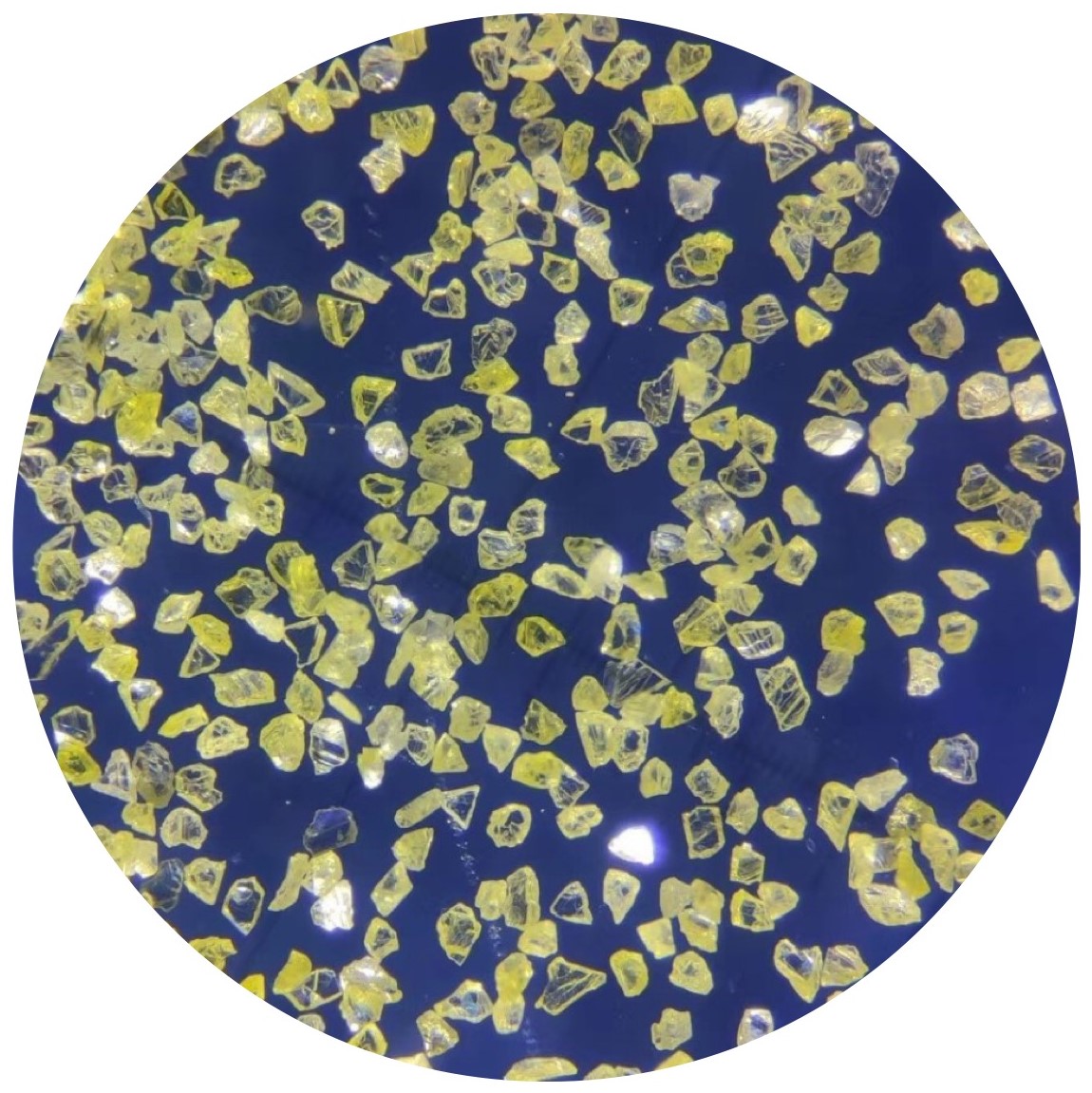

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for OEM/ODM Manufacturer Cerium Oxide Polishing Powder - FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools – SinoDiam , The product will supply to all over the world, such as: Albania, Victoria, Gambia, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!