Factory supplied Diamond Hardest Material - Polycrystalline Diamond Compact PDC Cutters For Oil and Gas Drilling – SinoDiam

Factory supplied Diamond Hardest Material - Polycrystalline Diamond Compact PDC Cutters For Oil and Gas Drilling – SinoDiam Detail:

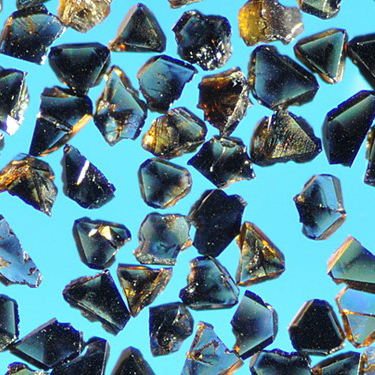

Polycrystalline Diamond Compact PDC Cutters For Oil and Gas Drilling

1. What is PDC material?

PDC- Polycrystalline diamond compact is composed of polycrystalline diamond layer and tungsten carbide substrate, the polycrystalline diamond layer possesses extremely high hardness and abrasion resistance whereas the tungsten carbide substrate would greatly improve the malleability and weld ability of the whole composite, the polycrystalline diamond compost is used oil well drilling petroleum, geology exploring, coalfield mining and mechanical industry.

Polycrystalline diamond compost (PDC) cutter inserts for drilling suitable for soft to hard geological terrane according to customers’ demand we can offer polycrystalline diamond compact with claw structures and chamfer types whether or not grinding and polishing, we can supply PDC cutters with special shape by customers’ order.

GAS series PDC cutter for petroleum and gas drills has high impact resistance and wear ratio, long service life and high efficiency of drill under rugged environment. suitable for soft and medium aggregate rock formations.

2. Specification of GAS series PDC cutter

|

Code # |

Diameter (mm) |

Height (mm) |

Diamond Table |

Charmfer |

Wear Ratio |

Impact Resistance |

|

GAS1308 |

13.44±0.05 |

8.0±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>1600 |

|

GAS1313 |

13.33±0.05 |

13.00±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>1600 |

|

GAS1608 |

16.0±0.05 |

8.0±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>1800 |

|

GAS1613 |

16.0±0.05 |

13.00±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>1600 |

|

GAS1908 |

19.0±0.05 |

8.0±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>2000 |

|

GAS1913 |

19.0±0.05 |

13.00±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>2000 |

|

GAS1916 |

19.0±0.05 |

16.0±0.1 |

1.8~2.0 |

0.41±0.05 |

>40 |

>2000 |

3. Character of GAS PDC Cutter

1) With feature of high working efficiency, smooth surface

2) Advanced technics and strict process control

3) Long lifespan and stable performance

4) Competitive price and superior quality

4. Other PDC Cutter Shape

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Factory supplied Diamond Hardest Material - Polycrystalline Diamond Compact PDC Cutters For Oil and Gas Drilling – SinoDiam , The product will supply to all over the world, such as: Netherlands, Nepal, Cape Town, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.