China OEM Tin Oxide Polishing Powder - FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools – SinoDiam

China OEM Tin Oxide Polishing Powder - FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools – SinoDiam Detail:

FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCC58

|

Main Element | Fe, Co, Cu |

| Theoretical Density | 8.58g/cm³ | |

| Sintering Temperature | 850℃ | |

| Bending Strength | 1400Mpa | |

| Hardness | 98-102HRB |

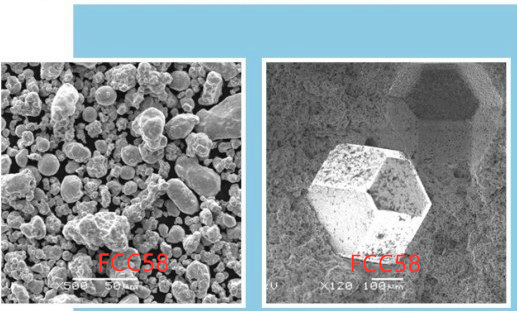

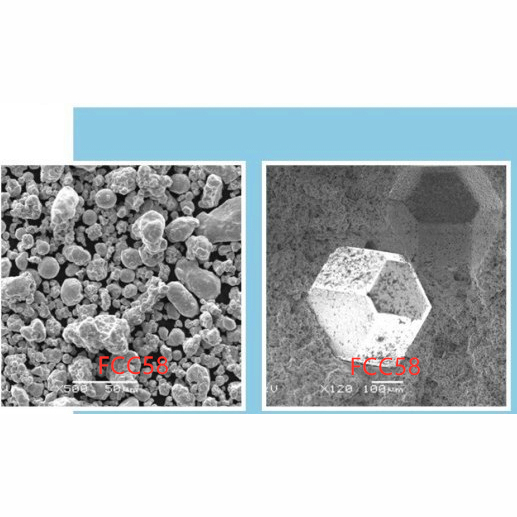

3. FCC58 Pre-alloyed Powder Character

- The powder has good wetting ability to the diamond and great mechanical granulating to other metal powders, the bond has a high toughness, strong impact resistance.

- Can be used on high quality diamond tools produciton, such as the diamond wire, diamond core bits, high quality granite saw blade, ceramic cutting blade

4. Usage Instruction for High Quality Ceramic Cutting Blade

- Metal Powder

- 30-50% FCC58

- + 3-8% Ni

- +25-35% Cu

- + 5-8% Sn

- + Fe for the balance

B. Diamond

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Diamond Concentration @ 9-12%

C. Sintering Temperature 840-860℃

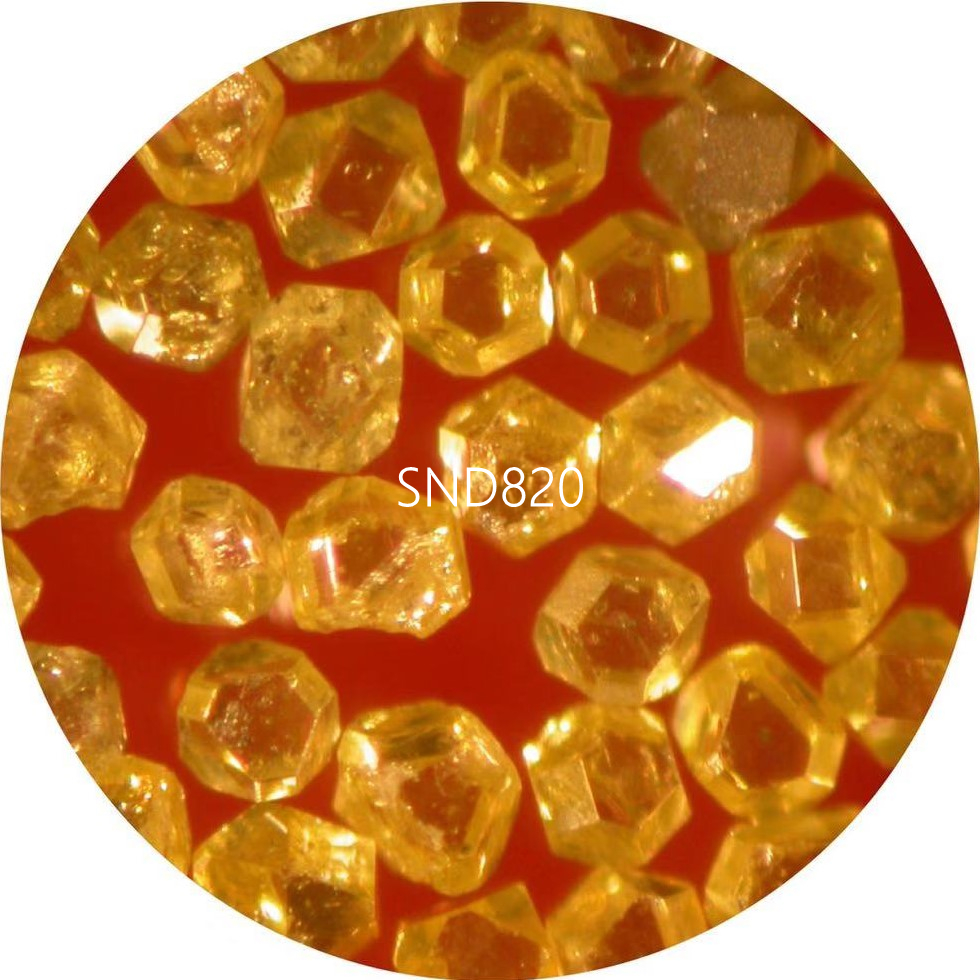

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for China OEM Tin Oxide Polishing Powder - FCC58 FeCoCu Pre Alloyed Metal Powder For High Quality Diamond Tools – SinoDiam , The product will supply to all over the world, such as: Vancouver, Jersey, Norwegian, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.