2021 High quality Industrial Diamond Powder - CCS25 Cu Co Sn Prealloyed Powder for High Quality Marble Saw Blade – SinoDiam

2021 High quality Industrial Diamond Powder - CCS25 Cu Co Sn Prealloyed Powder for High Quality Marble Saw Blade – SinoDiam Detail:

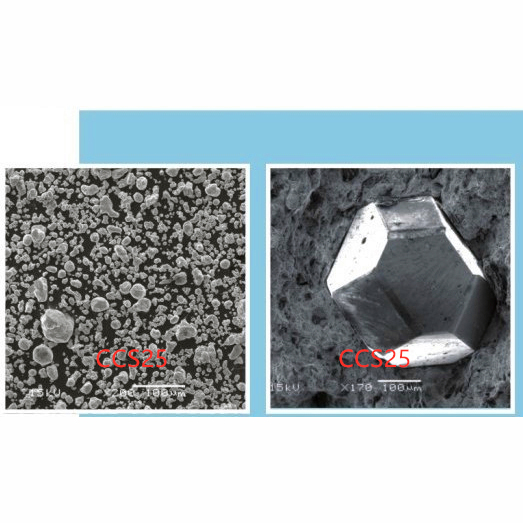

CCS25 Cu Co Sn Prealloyed Powder for High Quality Marble Saw Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of CCS25

|

Main Element | Cu, Co, Sn |

| Theoretical Density | 8.29g/cm³ | |

| Sintering Temperature | 760℃ | |

| Bending Strength | 800Mpa | |

| Hardness | 85-95HRB |

3. CCS25 Pre-alloyed Powder Character

- The Sintered Structure of the product is uniform, fine and compact, the diamond is wetted and mechanically wrapped. The bond main character is “Tough & Friagility”, great wear resistance and comprehensive quality performance.

- Applied to medium to high quality marble blade, glass grinding wheel.

4. Usage Instruction for Mrable Saw Blade

- Metal Powder

- 50-70% CCS25

- + 25-35% Cu

- + 4-7% Sn

B. Diamond

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Diamond Concentration @ 20-25%

C. Sintering Temperature 760-780℃

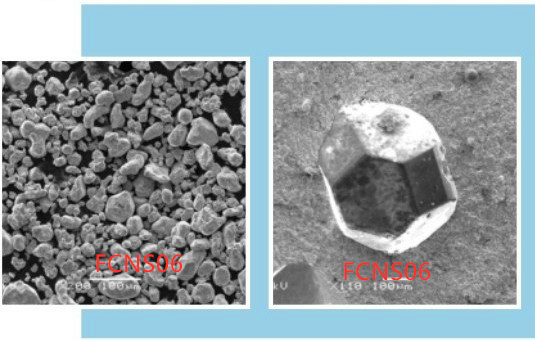

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for 2021 High quality Industrial Diamond Powder - CCS25 Cu Co Sn Prealloyed Powder for High Quality Marble Saw Blade – SinoDiam , The product will supply to all over the world, such as: Pretoria, New Delhi, Tunisia, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.