2021 China New Design Mbd Diamond Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam

2021 China New Design Mbd Diamond Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam Detail:

FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS06

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 8.05g/cm³ | |

| Sintering Temperature | 810℃ | |

| Bending Strength | 1100Mpa | |

| Hardness | 105-110HRB |

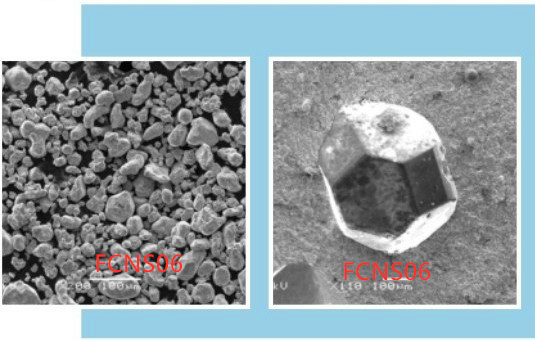

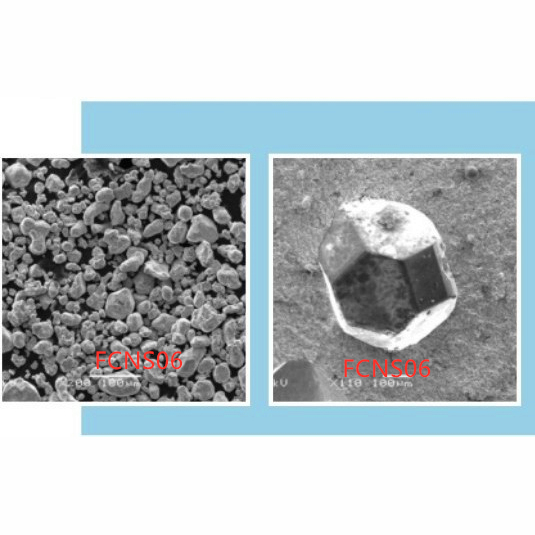

3. FCNS06 Character

- The Sintered structure of the product is uniform, fine and compact, it has good wetting and holding powder to the diamond, high hardness of the carcass, excellent wear resistance and good comprehensive performance of tools.

- The powder is applied to high quality small diameter diamond saw blade, ceramic cutting blades, ceramic gridning squaring wheel and scrapers.

4. Instructions for Making Ceramic Squaring Wheels.

- Metal Percentage:

- (40+60)% FCNS06

- + (15-25)% Cu

- + (6-10)% Sn

- + (2-5)% Ni

- + (8-12)% 663

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 70/80 @ 60%

- 80/100 @ 40%

- Concentration: (18-22)%

C. Sintering Temperature: 750-770℃

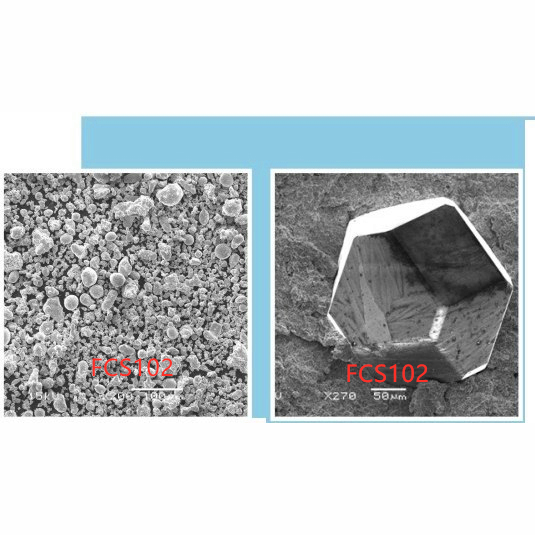

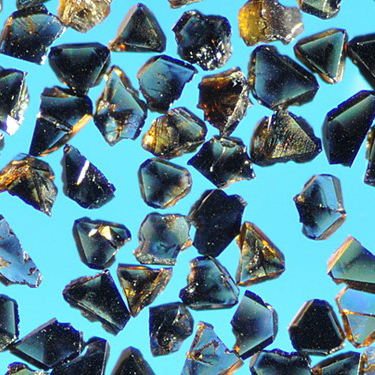

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Every single member from our large efficiency revenue team values customers' wants and company communication for 2021 China New Design Mbd Diamond Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam , The product will supply to all over the world, such as: New Zealand, Chile, Borussia Dortmund, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.