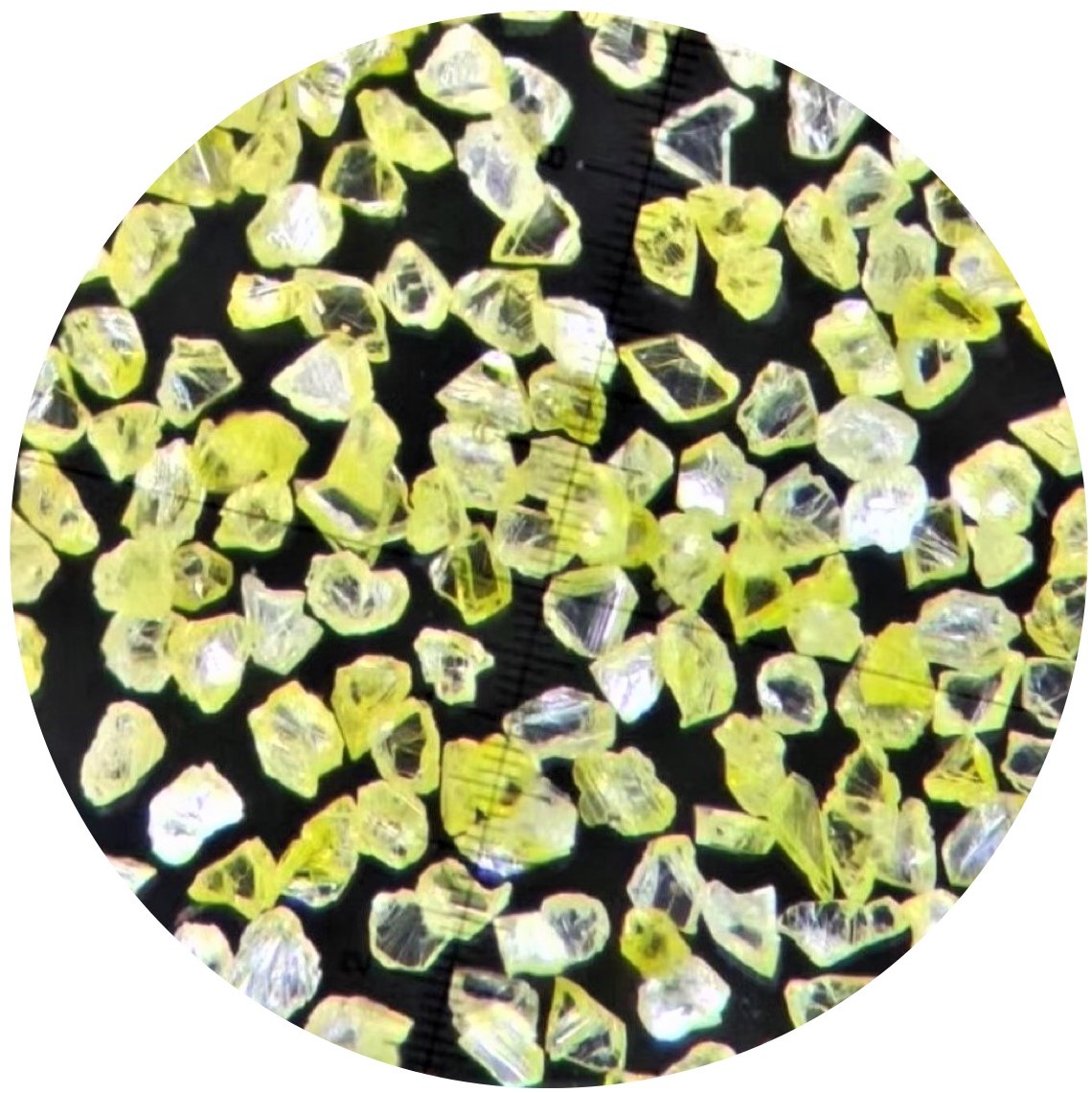

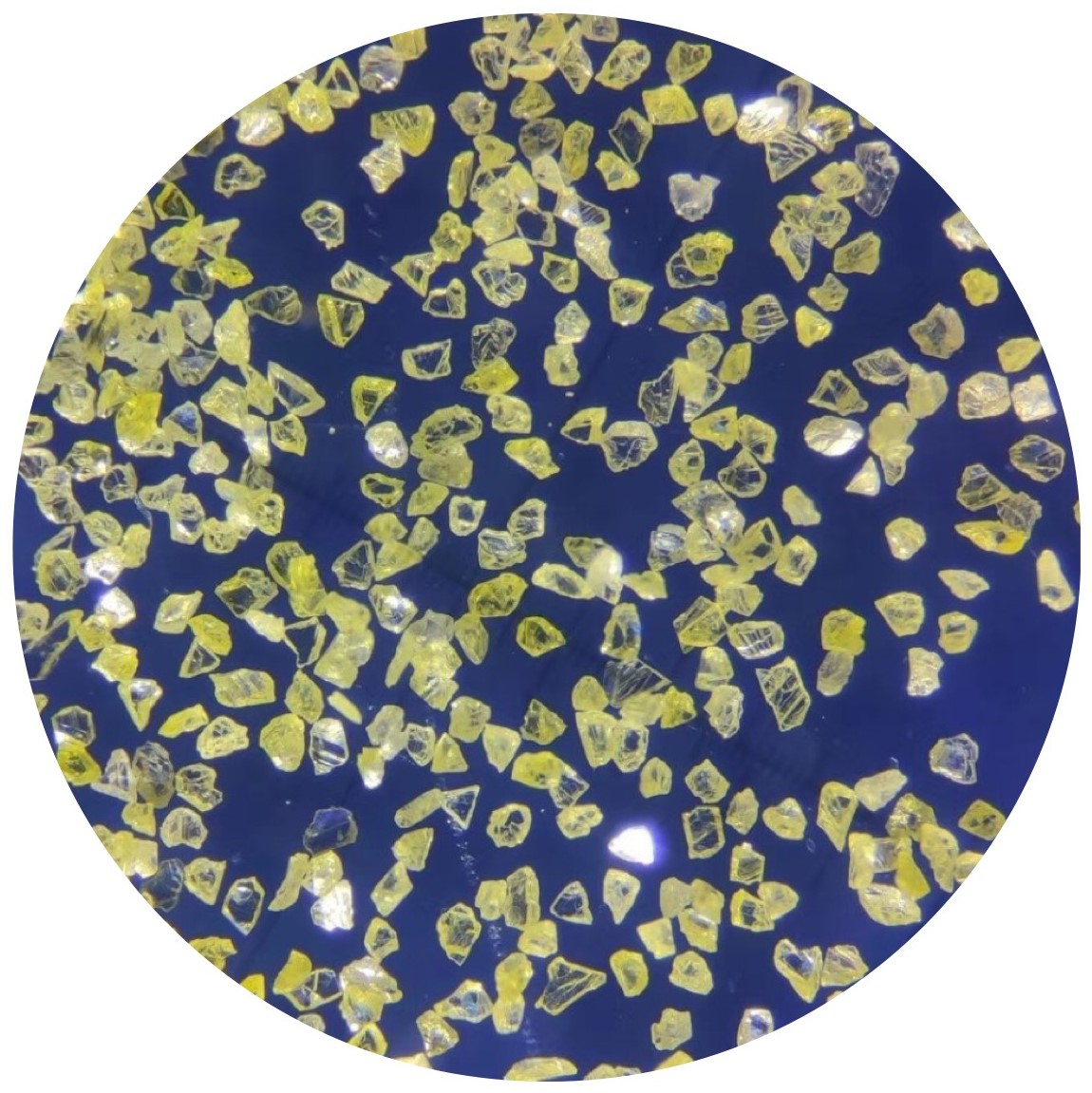

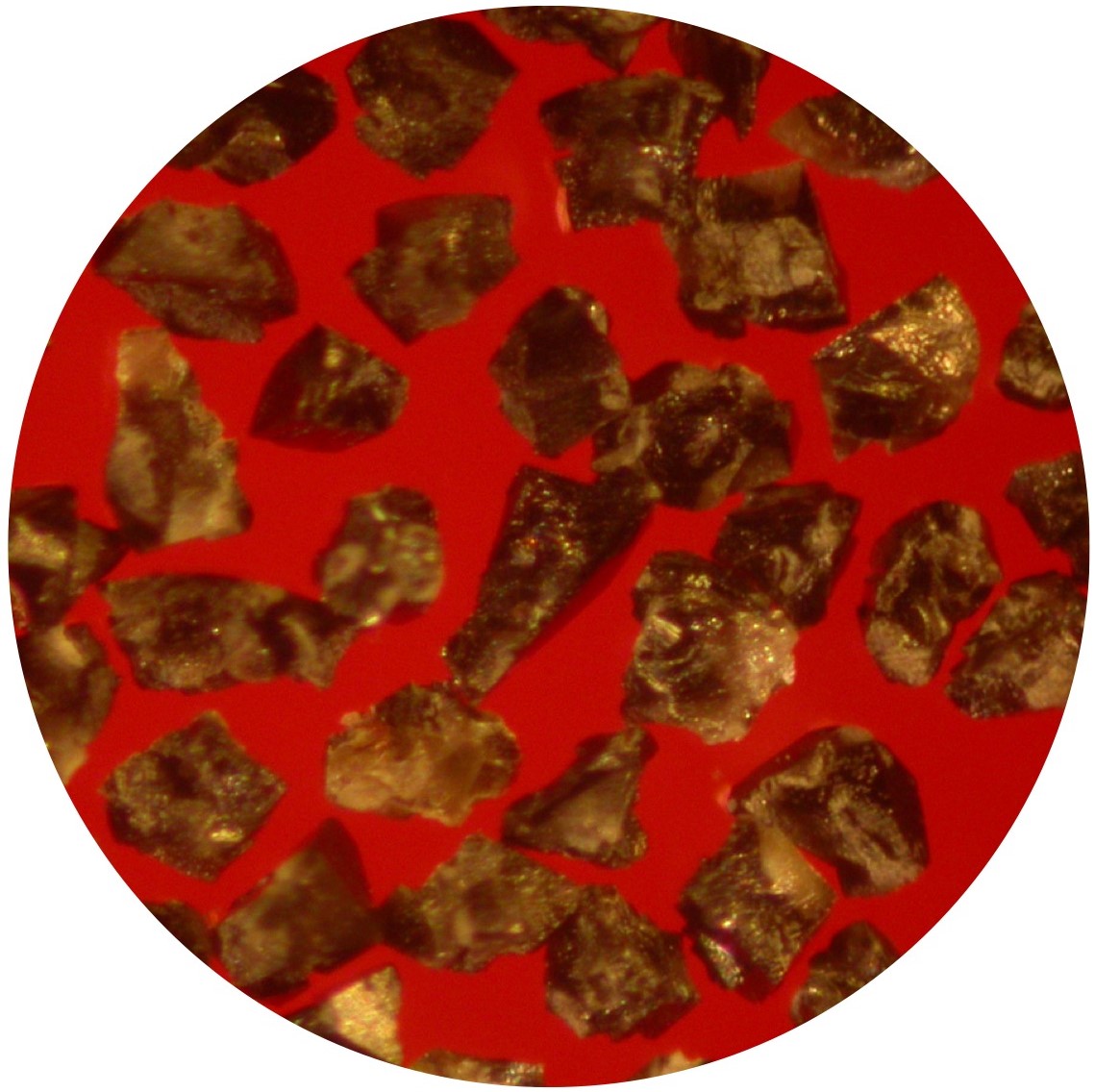

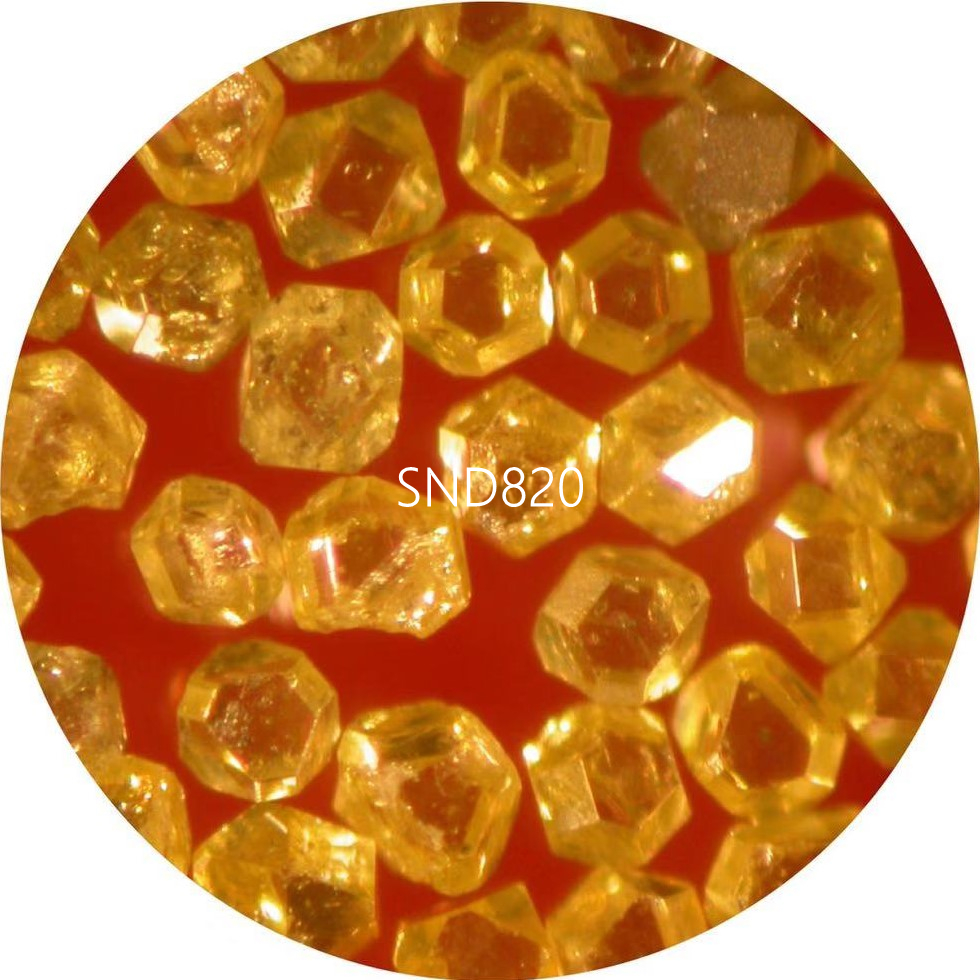

Synthetic Polycrystalline Diamond (PCD) For Cutting Grinding Non-Ferrous Materials

PCD is widely used for machining non-ferrous metals and alloys, such as aluminum, copper, aluminum/gray iron composites, as well as nonmetallic materials such as wood, chipboard, ceramics, plastic, rubber etc., where high abrasion resistance and good surface finish are required.

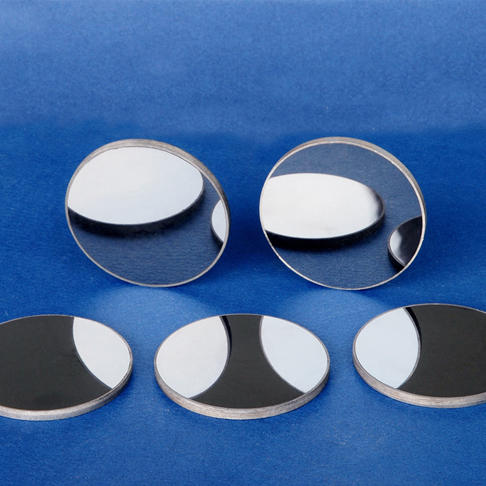

SinoDiam International offered a wide range of PCD for different application, and can cut the segments

size as the customer request

| Code # | Diameter(mm) | Diamond layer (mm) | Height(mm) | Diamond size(μm) | Feature | Application |

| SDPD032-A | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 30+2 | Extremely high abrasive resistance. Impact toughness is strengthened by the order of 025-A,025-B,032-A and 032-B, EDM cutting performance is strengthened by the order of 025-A,032-A,032-B and 025-B | Used in highly abrasive materials, such as ceramic, hard metal, silicon carbide, stone and laminate flooring. |

| SDPD032-B | 48.0 | 0.5±0.15 | 30+2 | Specially used in chipboard and other places where require rough feed. | ||

| SDPD025-A | 48.0 | 0.5±0.15 | 25 | Used in laminate flooring, density board, carbon fiber materials, silicon carbide, high-silica aluminum alloy. | ||

| SDPD025-B | 48.0 | 0.5±0.15 | 25 | Used in the manufacturing of common wood saw blade and products requiring EDM. cutting. | ||

| SDPD012-A | 48.0 | 0.5±0.15 | 10+2 | Combining high abrasive resistance, impact toughness and high degree of surface finish. Abrasive resistance is strengthened by the order of 010-C,010-B,012-A and 010-A. Impact toughness is 010-A,012-A,010-B and 010-C, EDM cutting performance is 010-A,012-A,010-C and 010-B. | Used in fine processing of circuit boards, silicon-aluminum alloy and copper alloy | |

| SDPD010-A | 48.0 | 0.5±0.15 | 10 | Used in processing of wood, circuit boards, low silicon-aluminum alloy and fine ceramics. | ||

| SDPD010-B | 48.0 | 0.5±0.15 | 10 | Used in manufacturing all kinds of segments with EDM cutting. | ||

| SDPD010-C | 48.0 | 0.5±0.15 | 10 | Used in the places with fine processing where require rough feed and low abrasive resistance. | ||

| SDPD005-A | 48.0 | 0.5±0.15 | 5 | High impact toughness, suitable for EDM cutting, extremely high degree of surface finish. | Used in the places where require high degree surface finish, such as low silicon-aluminum alloy, non-ferrous metal, semiconductor and plastic. |

Write your message here and send it to us